|

|

||

Remember: Press F11 for a

full screen view of this page. |

Web Counter when published 1

985 336 |

|

" Newlands and the Goldscope Mine " Date & start time: 24th April 2022. 11 am start. Location of Start : By the red phone box, Loweswater, Cumbria, Uk. ( NY 143 211) Places visited : Newlands , Castle Nook, Pluckhor Mine, Long Work and Goldscope Mine. Walk details : 6.9 miles, 1200 ft of ascent, 5 hours 30 mins including significant stops. Highest point : Part way up Scope End, 1015ft - 312m. Walked with : Thirteen Society members plus two guides, Mark Hatton and Mike Oddie. Weather : Sunshine but a cool easterly breeze on occasions. Organised by the Lorton and Derwent Fells Local History Society |

|

There are several social groups in the valley, some based on walking, some based on exploring local history, or of many other interests. Today two of those interests combined to provide the opportunity to walk into the 'history' of the Newlands Valley. - - - o o o - - - The Cumbrian Fells are famous nowadays for classic grassy open fells, mountain views and fell walking but in the olden days they were a hive of industry and Keswick for a short time was the copper, lead and graphite capital of the world. Our history group of a dozen or so folk meet in the Newlands valley to learn about that local history, with the assistance of two brilliant local experts.

Newlands Church on a beautiful Sunday morning. We were to meet at the Church Bridge parking area but it's holiday time so it was hard work finding a space.

Our group of thirteen were organised into some sort of order by our two guest leaders, Mark and Mike. After a quick explanation of the plans for the day and the offer of hard hats if you hadn't brought one, we were on our way.

Mark Hatton and Mike (both in red) are members of a Cumbrian mine exploration group CATMHS, Cumbria Mines History Society, and have spent many hours exploring old mine workings in the Lakes. They were to guide us round and impart their knowledge so that we would end the end the day much better informed about what we would normally pass by, hardly noticed on a fell walk or on outing into the hills.

Our walk would take us up the valley track to the head of the first Newlands Valley. To the left is Dale Head, then Hindscarth with Scope End (and Goldscope Mine) facing us centre photo. To the right is Robinson, with High Snab Bank being the ridge with the white building at this end of it.

First we would walk up the valley to "discover" the oldest working in the area, which date to the sixteenth century. These were dug by the German miners brought over by Queen Elizabeth 1st in the 1560's. - - - o o o - - - She created a consortium called "The Company of Mines Royal", a joint stock company in collaboration with German expertise. The German Company that supplied the men and technology and much of the finance was called “Haug Langnauer & Co” and records still exist back in Germany of all the original work reports and employment records from 350 years ago. On the home front Britain needed copper wire to make wool-carding combs, to support the important wool trade of the day. Queen Elizabeth 1st also needed the copper to make brass for weaponry, to protect against the possible invasion by Phillip of Spain. What was worse, Britain's supplier of all modern weapons at that time was also Spain, so her defence capabilities were at risk. She needed copper ! - - - o o o - - -

First stop were the workings of the later Castle Nook Lead Mine, which had tunnels (adits) higher up the fellside and spoil heaps that lay either side of the track.

Our main objective at the end of the valley was the Pluckhor mines, the spoil heap from which can be seen ahead. These were thought to be the first, but not the most productive copper workings in the valley. [ It is possible that small traces of copper was found here in the 1200's, during the rein of Henry III. ]

An ancient sheep fold post-dates the even older workings, the spoil from which shows that classic red copper tint.

Mark pointed out a flat rock that had two large hollows in it. This was a bench or anvil upon which a larger piece of extracted rock was placed, which was then broken with hammers into smaller pieces. This continual action would have worn away the stone to make the indentations. Good ore was placed in a basket of some sort, the waste was cast aside close by (see the red stone). Picture the scene !

Water was always a problem, especially if it rained. This excavation has filled due to Cumbrian rainfall and lack of drainage, but it has preserved the wooden props for us to see.

Close by a large sloping mine was explored by Mike and his torch. This section was kept dry by a tunnel lower down which drained the water away.

The Pluckhor Mine can be seen across the way as we explore Long Work. This excavation has been incorporated into a more recent sheepfold, the high sides saved on building dry stone wall to enclose sheep.

A 'conglomerate boulder' was pointed out by Mark, so we went over to explore.

He asked us what we thought it was ?

It was made up of standard size, richly coloured rock, quite small in nature.

This contrasted markedly from the surrounding spoil heaps.

The answer was that this is pure copper ore, broken by hand and stored in a heap ready for transportation to Keswick to be smelted. It was estimated to be about 15 tons of ore but why was it never taken away and used, after all the effort in extracting it ? The answer is possibly that a fall in the market price made it uneconomic to transport . . . or the company digging it went bust ! Some historians believe the Keswick Smelter was destroyed in the 1640’s by Parliamentary forces during the English Civil War. As a result the Copper Ore could no longer be processed so this ore and mining in general was abandoned.

Still it made a good place for a group photo today, the one above with Mark in it and this one taken by him, with myself in the photo. Suffice to say to would-be prospectors, this copper ore is now worthless as the copper content will have leached out due to the intervening 400 years of rainfall !

The 1560's mines explored, we started back down the valley by walking across to join the miners sled track which has zig-zagged its way down from more workings high on the face of Dale Head.dale head mines

Back down the valley past an old mine building that has a new lease of life as a climbing hut for the Carlisle Mountaineering Club

The gorse is in bloom and smelling sweetly as we cross the river on the path to Low Snab Farm and the Goldscope Mines

An old farm implement for harvesting hay, lies rusting alongside the track.

We climb the spoil heaps to reach the top of the "German Level" of the mine area.

We're on the outdoor processing floor where the rock was broken and refined, the waste material being cast aside into spoil heaps that cover the valley floor. The metallic nature of the waste has prevented re-growth of the grass in this area.

The view down the valley to the distant Skiddaw Fells, across the top of the spoil heaps. Generally the fine spoil is hand processed waste (16th century), the larger rock pieces tend to be later, post Elizabethan, bigger pieces being created once explosives became more commonly used in mining.

To the untrained eye it looked like an ordinary tunnel But with Mark's expert help we were shown the symmetrical, smooth, hand chiseled rock of the 16th century German workers. The tunnel would have originally been no wider than was needed to extract the ore vein and carry the rock out in bags. Later widening of the tunnel to allow a rail track improved efficiency destroyed much of the early German surfaces.

The gully to the left would have carried a continual stream of water to the outside . . . more of that shortly.

This tunnel took ten years to dig and was very disappointing due to the poor nature of the vein of copper, but suddenly a wide and prosperous seam of ore was found and profits soared.

We are into a large cavern that once held a twenty foot waterwheel. This was fed by a water leat carved through the mine, feeing a supply of water to provide motive power for the machinery in the mine. From here the mine went down six levels so rag and chain water pumps and hauling lines were needed to keep the lower levels dry and to extract the ore. The excess water was drained by the tunnel we had walked along.

His return, remarkably clean despite his travels !

Back out into the sunshine, albeit it with a cool easterly breeze.

Time for a spot of lunch.

As Mark had only taken half the party in on the first exploration, the second 'team' donned hats and torches to have their turn underground.

- - - o o o - - -

To complete the story we had the chance to walk around Scope End and view the area on the opposite side of the fell where the vein re-appears on the surface.

These are surface excavations of the ore vein which are nowadays full of water. Perhaps they were called 'pan holes' because they would have been kept clear of water by emptying with pans ?? Alternatively they may have been called that name because they would have produced copper used to make cooking pans and other utensils.

Mark also pointed out some of the hand cut levels used to access the seam. We are in the area above the old water wheel cavern where the miners dug upwards to expose the seam all the way to the surface. - - - o o o - - -

Once outside we were also able to make sense of an old footpath. This was the overgrown external water channel that led into the mine and water wheels and out through the St George's Level. It was fed with water from a dam and reservoir in Little Dale, high on the fells between Hindscarth and Robinson.

The leat also fed other water wheels for the later lead mines that graced this side of the hill.

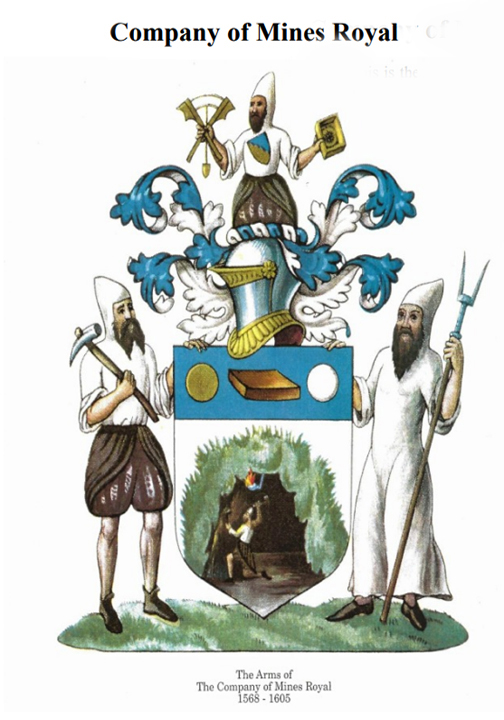

- - - o o o - - - This area of the mine also yielded lead ore in later years and it was against the backdrop of the waste scree that Mark explained about the Company of Mines Royal, set up by Queen Elizabeth 1st in the 1560's.

Their crest and coat of arms depicts the miners (with the pick) and smelters (with the protective coat) plus the top chap who seems to be holding an inclinometer for aligning the tunnels and ensuring drainage and flow of water. Pictured below was a miner at work and the central shield with possibly brass, copper and lead ingots, products of their work.

All that remains to do was to walk back down the fell to Newlands Church and the cars. Mark said that during the time of the mining, Low House Farm seen below was a busy pub known at The Sportsman Inn.

|Passing Low Snab Farm . . . sadly not appearing to offer teas any more.

Our conversations over the day exploded a few myths . . . * Goldscope Mine never produced any gold. The name is thought to be a corruption of Gottes Gab (God's Gift). * Elizabeth didn't commission the copper to clad her warships (that happened 200 years later) * The mines were brought no profit to the local landowners as the mines potentially held gold and pearls (?) so were deemed the property of the Crown. * The first large scale mining was undertaken by immigrant German miners brought over by the joint stock company, Mines Royal. * Cumbrian sausage was not a local invention . . . it was a development of the German bratwurst sausage brough over by the miners ! Many, many more topics were covered in our discussions today on what had been a remarkable day out.

A big thank you to both Mark and Mike for their leadership and for imparting their knowledge about the life of the early Cumbrian miners. A big thank you also to The Local History Society for organising the day. - - - o o o - - -

- - - o o o - - -

- - - o o o - - - |

Technical note: Pictures taken with my old Canon EOS 1100 Camera and some others contributed by Mark himself.

Resized in Photoshop, and built up on a Dreamweaver web builder.

This site best viewed with . . . a better understanding of the world we see around us, but don't always notice.

Go to Home Page . . . © RmH . . . Email me here

Previous walk - 21st April 2022 - Burgh by Sands - The Mob

A previous time up here - Wed 12th August 2009 A direct ascent of Dale Head

This walk organised by the Lorton and Derwent Fells Local History Society

Previous 'History events' - 20th October 2013 - Local History in 20 Objects - 1st November 2017 - History Society Trip to Carlisle

My next walk - 25th April / 5th May 2022 - Blencathra - Twice